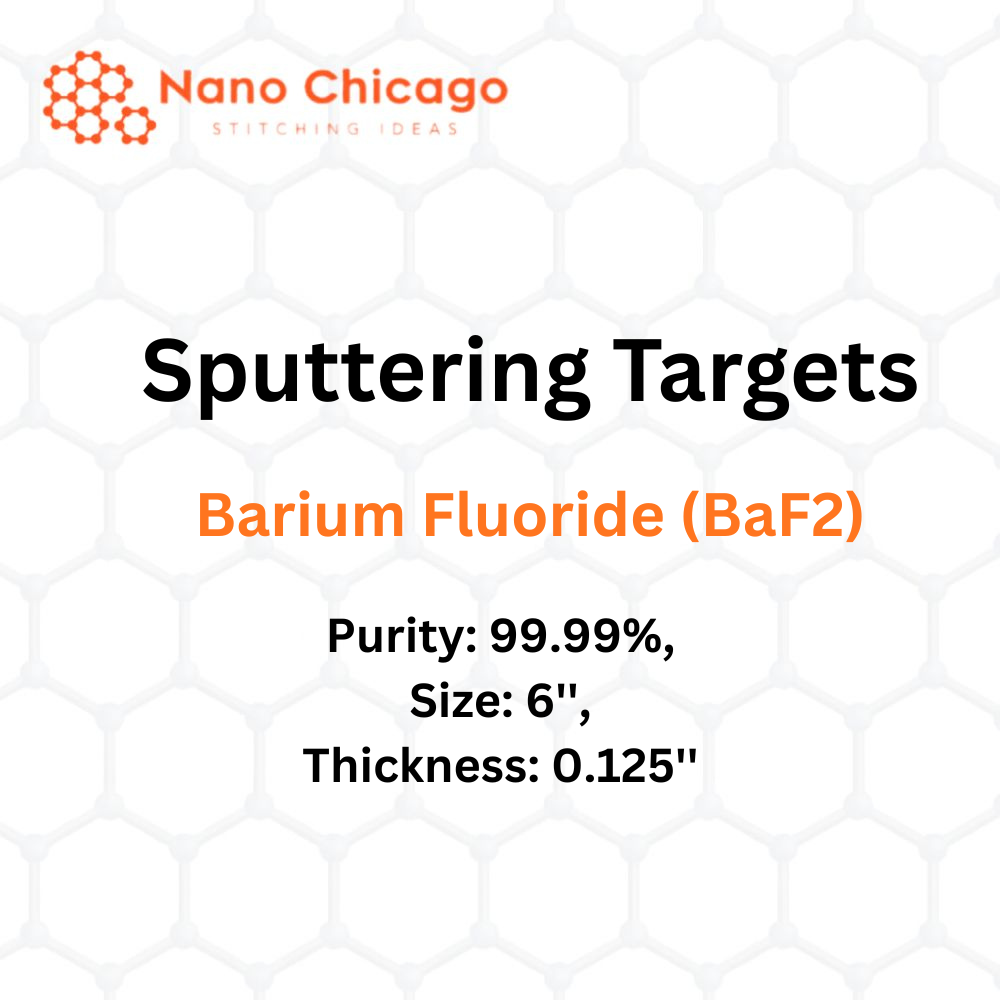

Barium Fluoride (BaF₂) Sputtering Targets

Purity: 99.99% | Size: 6” | Thickness: 0.125”

Sputtering is a reliable technology for depositing thin films onto a wide variety of materials and substrate shapes. The process using sputter targets is highly repeatable and scalable, suitable for small research projects as well as medium-to-large production batches. Chemical reactions can occur on the target surface, in-flight, or on the substrate depending on process parameters. Despite its complexity, sputter deposition provides precise control over film growth and microstructure.

Applications of Sputtering Targets:

-

Thin-film deposition by eroding material from a “target” onto a “substrate,” such as silicon wafers.

-

Semiconductor etching, where high etching anisotropy is required and selectivity is not a concern.

-

Analytical applications, including secondary ion spectroscopy (SIMS), which measures the composition of the target material and detects trace impurities.

Sputtering targets also have applications in space research. Sputtering contributes to space weathering, altering the physical and chemical properties of airless bodies like asteroids and the Moon.

About Barium Fluoride (BaF₂):

Barium fluoride is a chemical compound of barium and fluorine, forming transparent crystals. It is effective in the 10–20 µm infrared wavelength range. Industrial applications include aluminum metallurgy, enamel and glazing frit production, and welding agent preparation. In aluminum refining, BaF₂ acts as an additive to achieve bright reflective surfaces via chemical polishing. In flux brazing of aluminum and aluminum alloys, inorganic fluorides like BaF₂ are essential for removing oxide layers and ensuring high-quality surface treatment.