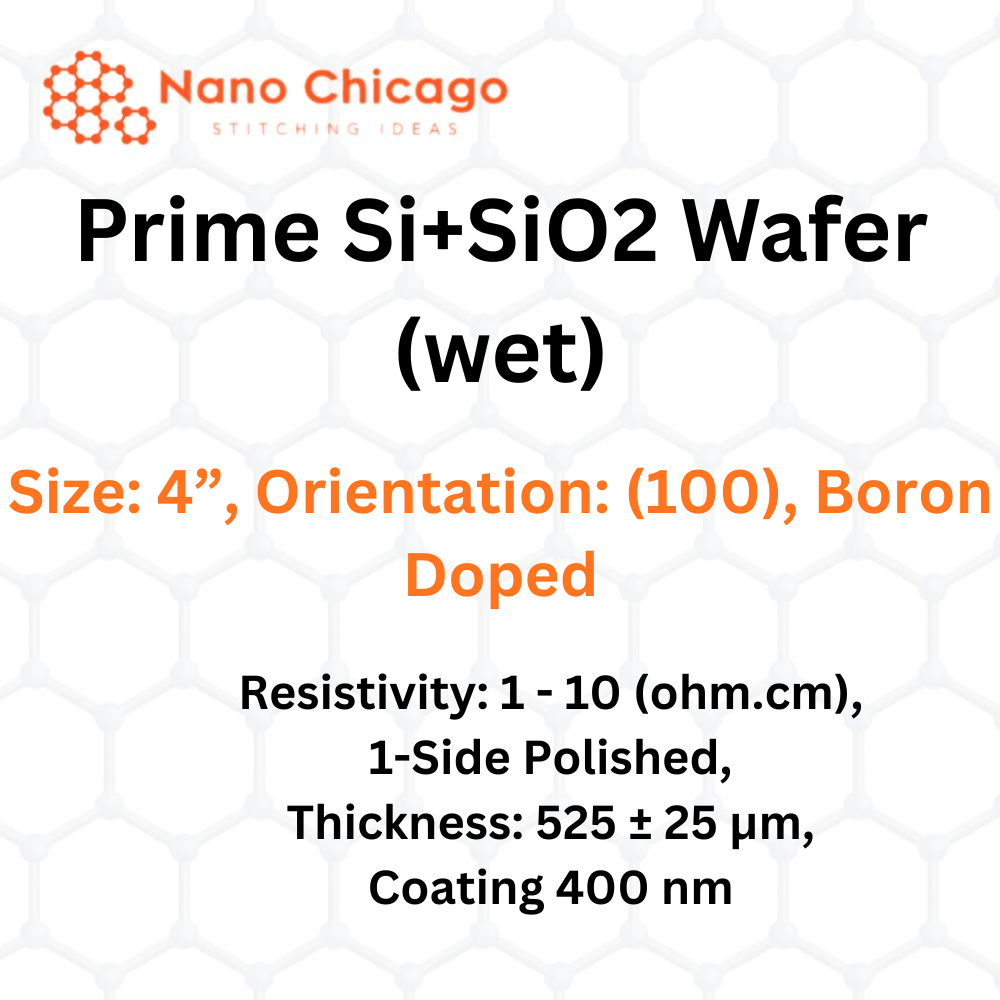

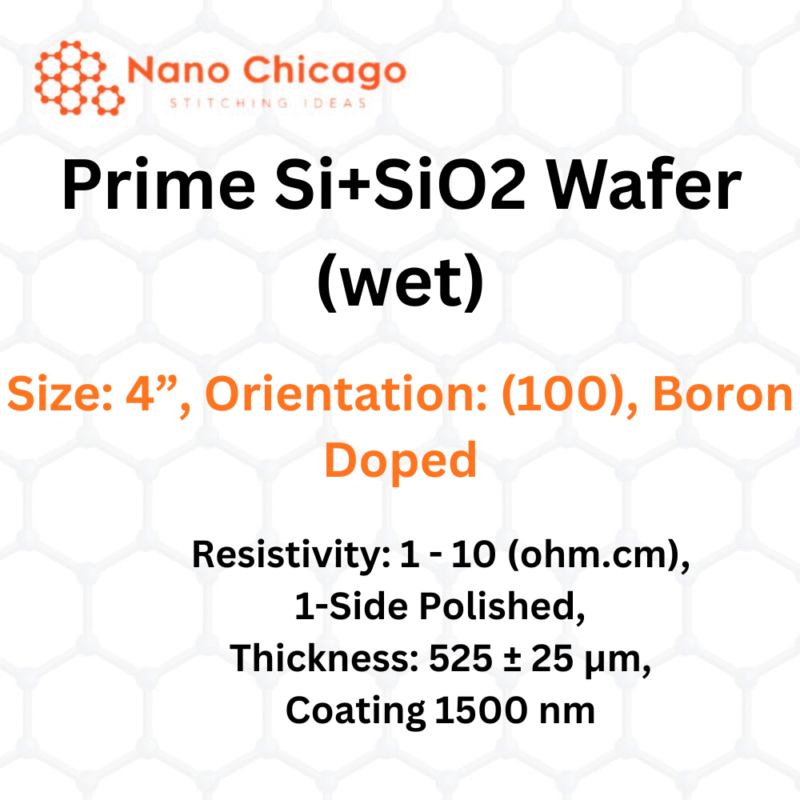

Prime Si+SiO2 Wafer (Wet)

| Parameter | Specification |

|---|---|

| Size | 4” |

| Orientation | (100) |

| Doping | Boron |

| Polished | One Side |

| Thickness | 525 ± 25 μm |

| Coating | 400 nm |

Silicon dioxide wafers, also referred to as thermal oxide wafers, are produced at elevated temperatures.

Thermal oxide is typically grown in a horizontal tube furnace at temperatures ranging from 900 °C to 1200 °C.

Unlike CVD-deposited oxide layers, thermal oxide is a “grown” oxide layer, offering higher uniformity and greater dielectric strength, making it an excellent insulating layer.

In most silicon-based devices, the thermal oxide layer is crucial for passivating the silicon surface, acting as a doping barrier and surface dielectric.

This method provides excellent thickness uniformity and purity, making it the preferred technique for producing high-quality thin silicon oxide layers.

Thicker oxide layers are generally produced through wet oxidation, where the growth rate is significantly increased.