Three Roll Mill Lab Model

Three Roll Mills are used for homogenizing, venting, and grinding a wide range of viscous materials. The Three Roll Mill Lab Model is designed with advanced control systems, an aerodynamic structure, and stainless-steel components, enabling powerful and consistent performance. It is an ideal instrument for small-volume laboratory production in applications such as electronic thick-film inks, high-performance ceramics, cosmetics, paints, printing inks, adhesives, epoxies, sealants, pharmaceuticals, chemicals, dental materials, carbon/graphite, food products, and other viscous formulations.

Agglomerates can be fully dissipated, and particle sizes can be significantly reduced, allowing finely dispersed, high-quality mixtures to be obtained. With the support of a professional technical and sales team, high performance, reliable service, and strong technical assistance are ensured.

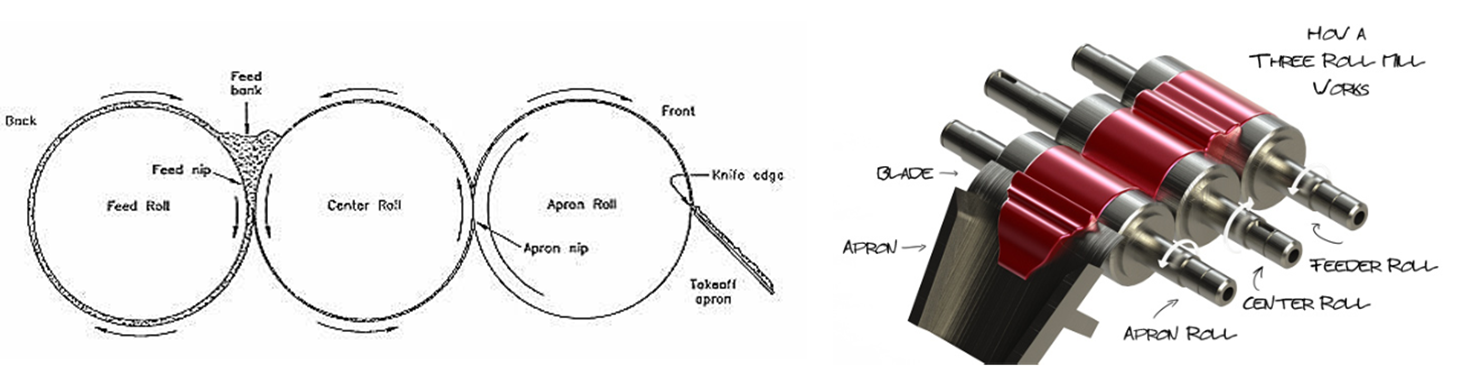

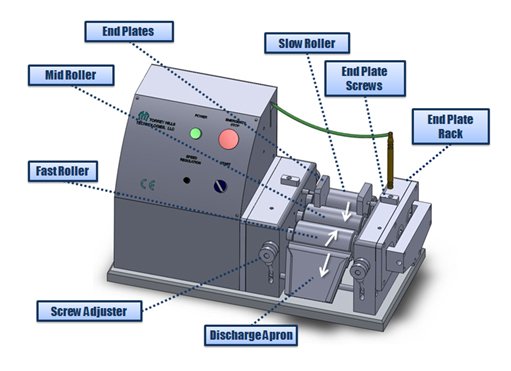

Three Roll Mills operate with three horizontally aligned rollers that rotate in opposite directions at different speeds. The very small gap between the rollers creates high shear forces that generate uniform dispersion and mixing. Material is introduced between the feed and center rollers, then transferred to the apron roller under strong shear forces. A blade positioned near the apron roller collects the processed material. Multiple milling cycles can be performed until the desired level of dispersion is achieved.

The machine consists of a robust base, cover, roller bearings, Teflon end plates, a collecting blade, a cooling system, and precision gears and wheels. Six bearing housings support the high-speed, medium-speed, and low-speed rollers. The medium-speed roller remains fixed, while the fast and slow rollers move horizontally to achieve the required grinding fineness. The apron can be manufactured from either steel or Teflon. A cooling/heating system is integrated into the rollers, allowing water or thermal oil to circulate through inlet and outlet ports to enhance process quality.

Special Properties of the Three Roll Mill Lab Model

-

Capable of producing 30 pounds or 3.75 gallons per hour, offering higher throughput than many competing models

-

Rollers manufactured from 420J2 stainless steel for corrosion resistance

-

Rollers compatible with cooling or heating operation

-

Ground to 5 µm concentricity and 0.5 µm surface finish for precision applications

-

Variable speed control for adjustable operation

-

Equipped with an emergency pull cord and easily accessible start/stop buttons for safety

-

Roller spacing adjustable manually via four hand wheels

-

Teflon end plates that can be easily adjusted

Technical Properties of Three Roll Mill Lab Model

| Parameter | Specification |

|---|---|

| Roller Material | Stainless Steel |

| Diameter of Roller | 2.5” (65 mm) |

| Length of Roller | 5.0” (127 mm) |

| Roller Speed Ratio (Fixed) | 1 : 2 : 4 |

| Feed Roller Speed | 0–108 rpm |

| Center Roller Speed | 0–216 rpm |

| Apron Roller Speed | 0–432 rpm |

| Motor Power | 3/4 HP / 55 kW |

| Weight | 165 lbs (75 kg) |

| Dimensions | 25” × 11” × 15” (635 × 280 × 381 mm) |